Cases

CASES

Categorization :

Industrial video borescope application field is very wide, this time is the industrial borescope in the clean pipeline application case introduction:

Customer profile:

The customer unit is a local enterprise in Shenzhen to do environmental protection water purification equipment, focusing on the detection of internal welding seams are welded well, whether there are surface porosity, slag, cracks and arc abrasions and other defects. We understand the needs of customers can work with customers to do visual inspection and analysis, through the technical aspects of communication to determine the solutions reached, we bring two sets of equipment on-site demonstration testing!

Site overview:

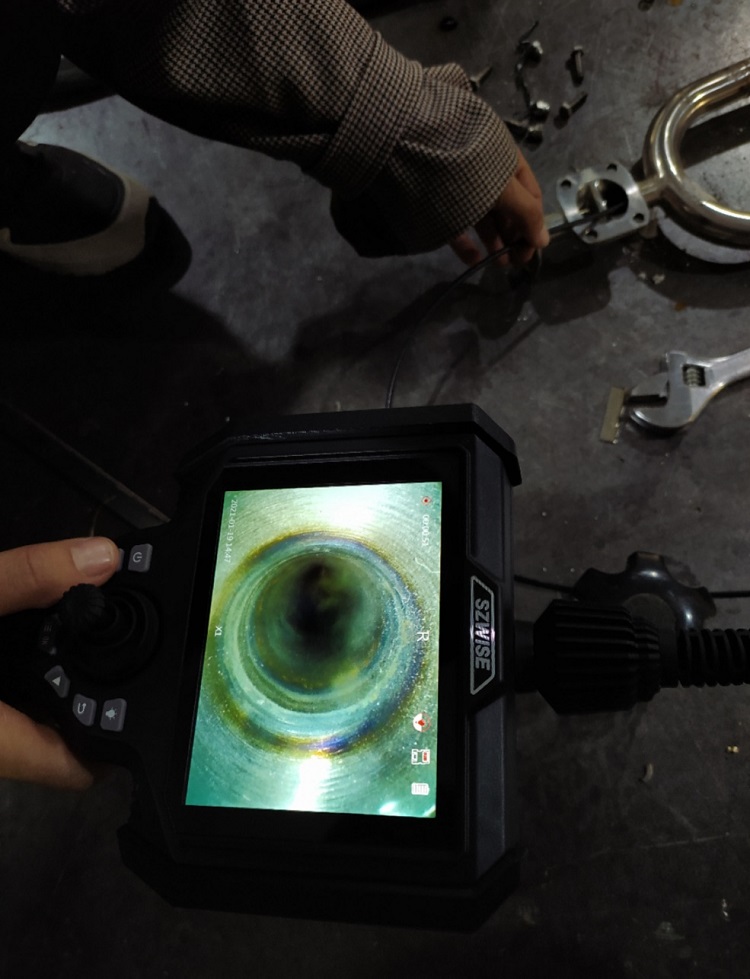

Customer representatives are: Technical Department, Engineering Department, the person in charge. In our communication again to listen to our technical staff to explain the product, the customer side of the relevant personnel in charge of the actual operation of the WS-K series of industrial endoscopes, due to the valve body mouth is too small, we chose a 4mm diameter equipment for testing, endoscopes inserted into the tube body can be realized in real-time 360-degree guidance, comes with built-in illumination, the inspector through the LCD monitor to observe the internal image, through the industrial endoscopes You can observe the internal condition of the tube body and take photos or videos of the defective parts with problems, and the customer fully affirmed the clarity of the equipment and other functions.

Solution:

1. 1 million high-definition pixels, can meet the internal observation of stainless steel pipe, welding scar defects in the pipe, internal residues and other defects, can be intuitive and clear judgment of the observation part of the qualification, taking pictures and video archive pictures and videos are clear.

2. 32G storage to prevent data loss, HDMI video output port, 360-degree swing head, but also replace the pipeline to be equipped with different pipe diameter size!

After the multi-faceted testing and communication, we ultimately solve the problem for the customer finally reached a cooperation agreement, while thanking the customer's trust and support of our company, can solve the needs of customers is our mission, but also the Division I of the customer's greatest return.

Factory : Building 19, No. 10, Songshanhu Park, Dongguan, Guangdong

Office : 18F, Pingshanshouzuo, Pingshan District, Shenzhen,Guangdong

E-Mail:jessicamo1106@gmail.com