SERVICES

Categorization :

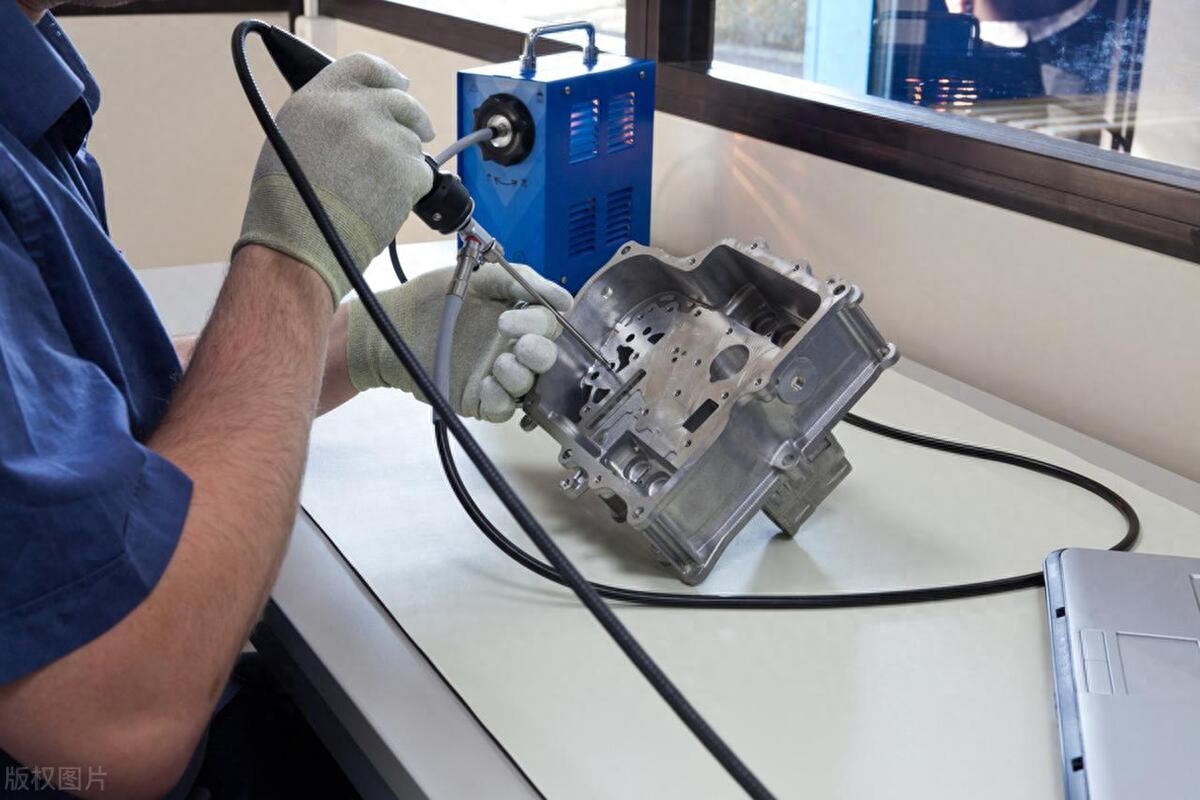

The utilization of industrial borescopes offers numerous advantages in various industrial applications, ranging from inspection to maintenance. These tools not only enhance the efficiency of the inspection process but also contribute to improved safety and accuracy.

Firstly, industrial borescopes provide a non-intrusive method of inspection. Without the need for disassembly or destructive testing, these tools allow for the examination of internal components and enclosed spaces without causing any damage to the equipment. This not only saves time but also reduces the risk of further complications or failures.

Secondly, the high-resolution images captured by industrial borescopes enable operators to conduct detailed inspections with precision. The clarity and magnification provided by these tools allow for the identification of even the smallest defects, cracks, or wear patterns. This enhanced visibility ensures that no issues are overlooked, leading to improved reliability and longer equipment lifespan.

Furthermore, industrial borescopes are highly flexible and versatile. They can be easily maneuvered into tight spaces and around obstacles, making them suitable for a wide range of inspection tasks. Whether it's checking the interior of a pipeline, inspecting the welding quality of a joint, or evaluating the condition of a turbine blade, industrial borescopes provide a comprehensive solution for visual inspection needs.

Additionally, modern industrial borescopes often come with advanced features such as wireless connectivity, image recording, and analysis software. These features enhance the usability and efficiency of the tools, allowing operators to share

Factory : Building 19, No. 10, Songshanhu Park, Dongguan, Guangdong

Office : 18F, Pingshanshouzuo, Pingshan District, Shenzhen,Guangdong

E-Mail:jessicamo1106@gmail.com